Power routing decides how a head bites, how it recovers after a strike, how hot the oil runs on dusty afternoons, and how often crews stop to reset or repair, and the truth is that drive systems trade speed, torque, shock protection, and heat in ways you can verify in the yard and in a short test row.

This article gives you a practical map of the choices, it explains how belts, direct motors, and gear stages behave in real brush, it shows what open and closed circuits change in response and temperature, and it ends with clear routines for setup and care so your head feels the same in month nine as it did on day one.

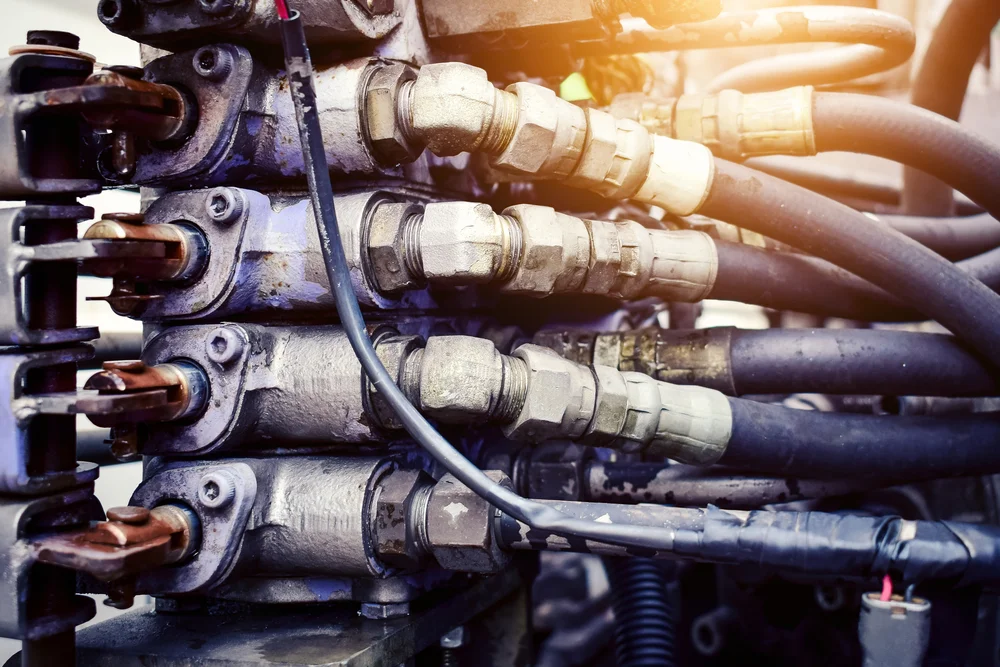

A clear view of the mulcher drive system helps you match hardware to the work rather than to the brochure, because stability under a modest bite, fast recovery after contact, and clean heat shedding are what keep production steady without cooking seals.

How power moves from carrier to rotor

Every design takes shaft power from the carrier and turns it into tip speed at the teeth while fighting variable load, shock, and dust, and the best systems hold a stable rotor speed on a modest bite, recover cleanly when material thickens, and shed heat through clean oil and clear airflow. Before you compare parts on a page, understand these aims because they explain why builders choose ratios, fuses, and housings the way they do.

Belt drive systems in practice

Belts bring ratio flexibility and a mechanical fuse that softens shock, they let you tune rotor speed to a stand without changing the motor, and they reward crews who keep tension and alignment in spec with quiet, steady production.

The daily checks are simple when they are familiar, and the steps for tension, alignment, and guard refit are laid out clearly in the operator guides, which turn those first minutes of the shift into the cheapest uptime you can buy.

Before you choose a belt head, confirm that guards open without tools, that pulleys are easy to sight for alignment, and that there is space to apply tension without stripping unrelated covers, then verify that the belt section and wrap angle match the torque you expect rather than the marketing claim. When the details are right the head slows without drama on a heavy bite, then comes back to speed as the cut thins, and heat stays under control because slip is rare and brief.

Here is a fast belt checklist you can use on a demo, keep it simple and consistent, then write the readings down so trends are visible later.

- warm the machine and check belt tension after the first pass, not cold

- sight pulley faces for alignment with a straight edge, confirm no wobble on spin down

- look for dust tracks inside guards that hint at slip or debris buildup

A quick conversation after the row helps set tension and alignment for the day, and that small habit explains why some crews run full seasons without a single scorched belt.

Direct hydraulic drive, behavior you can feel

A direct motor removes belts and their losses and reduces parts count, and when the circuit is matched the head feels very crisp because speed builds quickly and holds steady inside the efficient zone, yet the same simplicity can pass more shock to the motor and bearings if protection is weak.

You will want generous charge flow, clean case drain routing, and a relief strategy that keeps the motor in its safe window, and for an honest view of service life and layout choices it pays to read the practical build notes in our guide to durability engineering before you sign off on a spec.

“Drive layout is not a fashion choice, it is a promise about how your day will feel, if speed stays steady and heat trends are flat, the rest of the plan works.”

Elena Morris, Forestry Superintendent

Gearbox stages and protection details

A gearbox or intermediate stage lets a compact motor hit the desired rotor speed and torque, modern boxes with good sealing and magnetic plugs can live long service lives, and they reward heads that keep debris away from seals so heat and grit do not bake around the housings.

What matters is access for oil checks and fastener torque, and a shop rhythm that treats small readings as early warnings rather than afterthoughts, which is why pairing the head with structured maintenance checklists is a quiet way to prevent the classic gearbox failure that arrives one week before the busiest window of the year.

Hydraulic circuits and motor choices

Drive behavior depends on the circuit that feeds it and on the motor architecture, and you can feel the difference between an open circuit that returns to tank and a closed circuit that recirculates flow with charge makeup.

Startup behavior, recovery after a load spike, and the fuel bill at the end of the week all trace back to these choices, so test with warm oil and write the numbers down rather than guessing.

Open circuit and closed circuit, what changes in the cut

Open circuit heads are common when the carrier shares pumps with other implements, they are easy to instrument and straightforward to service, while closed circuit heads use a dedicated loop that holds speed very firmly with efficient recovery.

The right choice depends on your production goal and your tolerance for complexity, so standardize a quick yard routine built around warm oil, test ports, and relief verification, then fold that routine into your daily pre operation checks so small drifts do not turn into long hot afternoons on the job.

Variable and fixed motors, matching speed and torque

A fixed motor is predictable and simple, you pick a ratio and live within it, while a variable or two speed motor lets operators trade speed for torque as material changes along the pass, and that flexibility keeps the rotor in its efficient zone longer when people use it thoughtfully.

The benefit shows up on the fuel line and in temperature trends when crews avoid long minutes near reliefs, and practical ways to tune habits around throttle and bite are gathered in our field note on fuel efficiency tips, which turns small choices at the sticks into cooler days and steadier production.

Before you lock a motor choice, talk with operators about the stands they see most days, the time they spend in continuous brush versus intermittent contact, and the pattern of stops that happen around traffic or public edges, then write a simple decision rule that tells them when to select low or high and when to thin the bite. Short, specific rules beat vague advice, and they make variable hardware pay back quickly.

Here is a simple selector you can post in the cab, it saves arguments and keeps the rotor where it is happiest:

- use low speed when chip size grows, bite is heavy, or the head meets stringy material that drags speed down

- use high speed when brush is light, passes are long, and chip throw needs to stay low around sensitive edges

- return to baseline after each stand and record temperatures and pressures so you can see drift in a week

This is not theory, it is a small habit that keeps speed stable and oil cooler without slowing the job.

Reliefs, charge flow, and cavitation control that save parts

Protection is part of the drive, not an accessory, and circuits that give the motor clean makeup flow, that place reliefs where pressure spikes are managed rather than ignored, and that add anti cavitation checks near the ports have fewer failures.

Listen for inlet whine on startup, watch case drain temperature after a pass, and confirm that relief settings match documented values at operating temperature, because those details decide whether a stall becomes a short pause or a repair order.

Matching systems to jobs, setup and care

No single architecture wins every site, and the best choice follows the material, the contact with soil or rock, and the time the head spends near public edges.

The rest is discipline, verify numbers with warm oil, keep filtration in spec, and record readings so trends appear early.

Corridor work and continuous brush

Long corridors reward stable rotor speed, low heat, and simple routines that keep debris out of the cooler pack, which is why a clean belt stage or a well tuned closed circuit can feel efficient on spans and easements.

If your calendar is full of spans, easements, and rights of way, study the demand patterns in utility corridor clearing and choose the drive that holds speed gently while giving crews easy access to screens and ports for midday blowouts.

Rocky ground and intermittent contact

Sites with rock, wire, and uneven ground push shock into the system and invite debris to walk into seals, so pick a path with a predictable fuse and strong end protection, and plan for frequent visual checks around bearing faces and guard edges.

The behaviors and tradeoffs described in our field guide to rocky or uneven terrain will help you judge whether belts, a direct motor, or a gearbox stage is the safer choice for the stands you see most often.

Commissioning, logging, and long term care

Day one setup and daily discipline make the difference between a smooth season and a stack of repair orders, and the routine is not complicated when it is written down and followed without excuses.

Warm the carrier, confirm pressures at the test ports, check charge flow and case drain, verify belt tension or gearbox oil as needed, then log the numbers where the next operator can see them, and extend that habit with the practical care routines gathered in our guide to long term care of industrial mulchers so the machine feels tight through long windows.

Here is a short commissioning list you can run in one afternoon, it sets a baseline that protects your season.

- record idle and working pressures with warm oil and note ambient temperature for context

- clean screens and coolers once, then recheck temperatures to confirm airflow and debris control

- torque one tooth and one guard fastener to verify realistic field values and tool fit

Finish by posting the readings in the cab, review them during the pre start brief, and adjust the plan as trends appear, because this is how small checks turn into big savings without slowing production.